| Home |

| Misc. |

|

10-November-2017 Bertho Boman |

|

|

|

|

Introduction:

The mill is using a Taig spindle, a Consew brushless motor with speed control, PoKeys CNC57 motion controller, and Mach4 operating software. It is on my To-Do list to write up a description of it. Lathe vs. Milling Machine:

A lathe without a tool changer is limited to a single tool per operation plus maybe a rear cutoff tool. Using the mill there can be multiple tools at different fixed locations on the milling table. The desired tool is selected by moving the table to the tool location and then performing the desired operation.

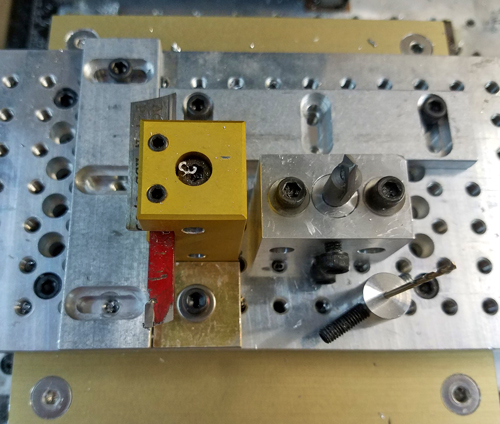

The front left red tool is a regular lathe bit. Behind it is a cutoff tool, on the front right is a drill bit and in the center right side a "V"-tool bit. There is space for several more tools on the milling table. Writing the G-code is an interesting challenge since there are extra tools to keep track of and the cutting directions can vary depending on the tool position relative to the spindle. All the G-code was hand-written. The speed and feeds have not been optimized in the video. A video of the machine can be seen on Youtube: Youtube VideoPreviously a custom CNC lathe was built for a specific application also using the Taig spindle. That project can be seen here: www.Vinland.com/CNC-Lathe.htmlHopefully this will inspire some people to try using a mill as a substitute for a lathe. There are obvious limitations but also additional features are available. For example, at the end of the lathe operation, the part can be locked into a holder and a milling bit used for regular milling operation. Bertho Boman

|