|

Introduction

There is a need for sensors to detect "home" position in machinery, for

example CNC milling machines. There are many choices but there is little

data about their accuracy (repeatable detect the same position).

This report is the result of my desire to know the capability

of the regular opto-interrupters commonly used as home sensors.

To reduce the variables and remove threshold sensing requirements from

the interfacing logic in the CNC equipment or a controlling PC,

I used an opto-interrupter with internal threshold logic. The model used is

made by Optek model# OPB917B. That model happens to have unusually long "arms"

but any model from the same series should have similar performance. The important

specifications are the sensor's aperture size; the smaller, the better.

The tested version has an sensor aperture of 0.010" by 0.060"= 0.254mm by 1.524mm.

This sounds discouragingly large, but it turns out that the performance

regardless is extremely good. Here is a link to Omron and the data sheet:

www.optekinc.com

OPB917B PDF data sheet

Equipment and Setup

I carefully mounted the opto-interrupter to a solid measurement platform and

I had a knife edge shaped interrupter blade mounted to a linear ball slide. The blade

was centered in the slot of the interrupter and the edge was carefully

aligned to be parallel to the internal measurement aperture of the sensor.

The interrupter was covered to avoid any influence or errors caused by external light.

The platform in turn was moved by a Mitutoyo digital micrometer head with

one micron (39 microinches) resolution. The slide was spring loaded against

the micrometer to take up any slack.

Electrically, the circuit was powered by a stable digital power

supply and the source LED was driven through a 470 ohm resistor. The

output was monitored by an LED with a 470 ohm current limiting resistor.

Measurements and Data

To check repeatability, I from an arbitrary start position found the On

and Off transition points when the interrupter switched states. I obviously had to be

very careful and very slowly turn the micrometer to move just one

micron at a time and then record the value when it switched. I have been

accused before of faking data, but then as now, this is real data; it

just works extremely well, much better than I expected. In a very short

summary: Repeatability never exceeded one micron!!

Repeatability

|

Repeatability Errors at Different Supply Voltages

|

| 10V Supply |

12V Supply |

14V Supply |

| On | Off | On | Off | On | Off |

| 102 | 79 | 111 | 90 | 118 | 98 |

| 102 | 79 | 111 | 90 | 118 | 98 |

| 102 | 79 | 111 | 90 | 118 | 99 |

| 102 | 79 | 111 | 90 | 118 | 99 |

| 102 | 79 | 111 | 90 | 118 | 99 |

| 102 | 79 | 111 | 90 | 118 | 99 |

| 102 | 79 | 111 | 90 | 118 | 99 |

| 102 | 78 | 111 | 90 | 118 | 99 |

| 102 | 79 | 111 | 90 | 118 | 99 |

| 102 | 79 | 111 | 90 | 118 | 98 |

Errors from Changing supply Voltage

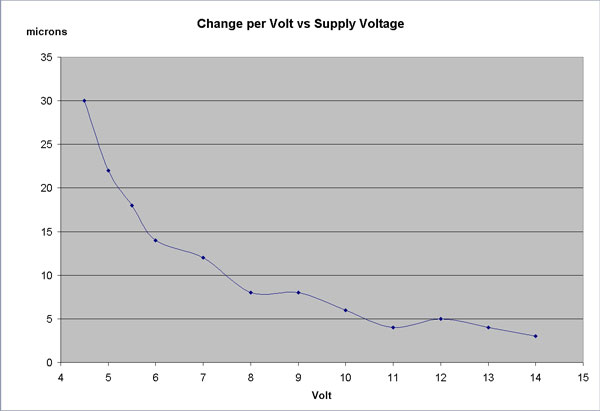

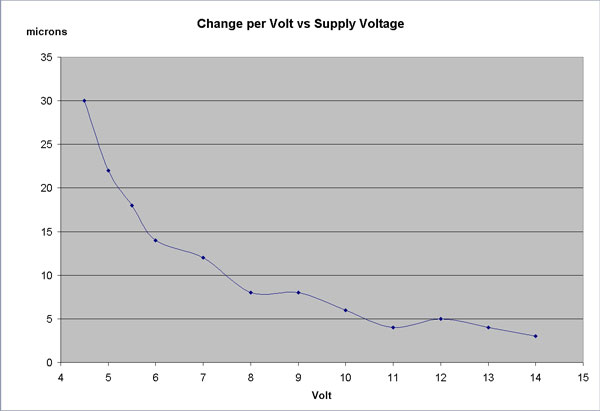

Please remember that the data below is displayed as micron changes

per volt supply change. It is really the slope of the curve in the

graph below. It might be easier to think about it in slightly more

practical terms by talking about errors per 0.1V change and dividing

all the error numbers by ten. For example, a change from 5.0 to 5.1 would then give

a 2.2 micron error and changing from 12.0 to 12.1V would give

an 0.5 micron error. This behaves just as expected for two reasons:

The percentage change becomes less and less the higher the supply voltage

because the voltage change becomes a smaller and smaller percentage.

Further, the interrupter has an internal voltage regulator and

providing a larger input voltage to it, it will work better.

|

#1. Errors caused by Supply Voltage

|

| Volt | Microns | Error/Volt |

| 4.0 | 226 | - |

| 4.5 | 241 | 30 |

| 5.0 | 252 | 22 |

| 5.5 | 261 | 18 |

| 6.0 | 268 | 14 |

| 7.0 | 280 | 12 |

| 8.0 | 288 | 8 |

| 9.0 | 296 | 8 |

| 10.0 | 302 | 6 |

| 11.0 | 306 | 4 |

| 12.0 | 311 | 5 |

| 13.0 | 315 | 4 |

| 14.0 | 318 | 3 |

Further Testing

My next step in the quest for accuracy is to do careful testing over temperature.

I did some very crude test with freezer spray and a heat gun and as a rough estimate,

I saw changes of about 30 microns going from 25C to 0C or to 50C. I really do not trust

those numbers so do not rely on them. I wanted to see if something

drastic happened versus temperature changes and it did not so that is very

encouraging. I also need to increase the measurement resolution by a factor of 10.

Summary

An opto-interrupter with internal electronics as tested works extremely well,

much better than expected. For best long-term accuracy in a machine environment

I will mount them in a protective enclosure and I have been thinking of having a

brush mounted on each side of the opening, with the bristles pointing against each other.

The sensing flag would slide in-between them and be wiped clean and the brushes would

prevent dirt from getting into the opto-interrupter.

Bertho Boman

Vinland Corporation

11600 NW 20th Street

Fort Lauderdale

FL 33323

(954) 475-9093

Email: boman01 at vinland dot com

www.vinland.com

|